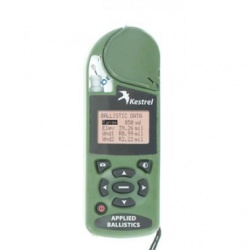

At Kestrel and Nielsen-Kellerman, makers of Kestrel Meters, weather is serious business! NK has been researching, designing, manufacturing and distributing Kestrel Meters for 10 years. NK's founders and lead engineers, Richard Kellerman and Paul Nielsen, are determined to make the most accurate and reliable hand-held weather devices available. They have developed four patented measurement technologies for the Kestrel family and continue to research ways to improve the Kestrel line and create new products to meet customers' needs. At LockhartTactical.com, we're proud to offer these robust, reliable instruments to you!

While it may not be obvious when you look at a Kestrel side-by-side with a competitor's weather meter, there are very important differences that make Kestrel the best choice for almost every application:

1) Certified and Guaranteed Accuracy

Every single Kestrel manufactured at Nielsen-Kellerman is calibrated for every single value, either directly against NIST-traceable standards or against an intermediary standard that is calibrated daily. Every unit is shipped with a FREE Certificate of Conformity that states what calibrations were performed, and the certified performance specifications.

What does that mean for the customer? They can be absolutely sure that their weather readings are accurate to the stated specifications. Some competing weather instruments claim the same specifications as Kestrel, but only Kestrel certifies their accuracy.

2) US Manufacturing

The entire Kestrel line is designed and built in the USA - no other handheld weather meter is.

Some electronic components have to be sourced overseas these days, but NK buys American wherever they can. Kestrel believes US manufacture is the only way they can ensure that every Kestrel will do its job right, and they also believe it's important to do their part to keep manufacturing alive and well in the US.

3) Field and Factory Recalibration

Not only is every Kestrel guaranteed accurate when it leaves the factory, but accuracy can be ensured by field and factory recalibration for years of reliable performance.

To field calibrate the wind or air flow readings, simply purchase and snap in a new impeller. For relative humidity readings, use the RH Field Calibration Kit. Field recalibration of the pressure sensor is possible, but not recommended as it has the potential to make the Kestrel's pressure sensor much less accurate if done incorrectly. Contact the manufacturer directly for detailed instructions and guidelines. The only sensor that cannot be field calibrated is the temperature sensor. The Kestrel's accurate temperature readings are due to the manufacturer's patented external thermistor, and over more than a decade of Kestrel sales, they've never identified one that needed recalibration.

You may also return your Kestrel to the manufacturer, for factory standard or NIST-traceable recalibration, as well as complete "tune-ups" including recalibration.

4) Patented Removable Impeller

The Kestrel impeller measures 1 inch across and turns on a Swiss precision pivot mounted on sapphire bearings. Its large size ensures accurate readings even if pointed off-angle from the wind, and its very low start-up speed allows measurement of the lightest puffs of wind. Units with smaller impellers simply can't match the Kestrel's performance.

If damaged, a new calibrated impeller can be purchased and popped in without tools, restoring like-new performance. Kestrel designed and patented this removable impeller technology, and it will keep your Kestrel Meter accurately measuring the wind speed for years.

5) Dual Temperature Sensor RH Measurement

Relative humidity is tricky to measure - particularly in a sealed product. But, with wildland firefighters among leading users of Kestrel meters, Kestrel knows it is essential to get it right.

Accurate temperature measurement is critical to calculating relative humidity. With Nielsen-Kellerman's patented Kestrel dual temperature sensor, it's not necessary to wait the 20 to 40 minutes that would normally be required for the unit temperature to equilibrate to the air temperature after a temperature shift. The Kestrel instantly and accurately calculates relative humidity accuracy of +/- 3% RH from 5 to 95%.

The humidity sensor in the Kestrel has been selected for long-term stability and reliable performance even at very low and very high humidity conditions. Every Kestrel is calibrated against NIST-traceable standards, and can be recalibrated in the field with the Kestrel Calibration Kit.

6) Pressure-Corrected Wet Bulb Temperature

Meters that provide wet bulb temperature readings without a pressure sensor assume standard atmospheric conditions, leading to highly inaccurate readings on low-pressure days, at high altitudes, or in any other "non-standard" situation. Kestrel meters offer wet bulb temperature readings only on our pressure-sensor equipped units, ensuring accuracy in all conditions.

7) Patented Temperature Measurement

Unlike most watches and other products with a temperature measurement, the Kestrel sensor is outside the case to ensure it measures the air, not your hand or pocket. The "curls" serve to further isolate the temperature sensor from the effects of the case temperature. Simply wave the Kestrel back and forth a few times and you'll have accurate air temperature readings in seconds.

And, since the Kestrel is completely waterproof, you can actually take water temperature and snow temperature readings. Just ask the US Biathlon team - they used Kestrel 4000's in the 2006 Winter Olympics to measure air and snow temperature to determine the appropriate wax to

use on their skis.

8) Product Tune-Ups and Certification

If you would like to have your Kestrel checked for accuracy and restored to like-new performance, Nielsen-Kellerman offers a Tune-up service that includes a new impeller, new batteries and full recalibration for a fraction of the original purchase cost. They also offer NIST-traceable Certificates of Calibration for industries that require it.

9) Leak and Drop Testing

Nielsen-Kellerman specifies IP-67 sealing for every Kestrel. This means that a Kestrel is totally protected from dust and can be submerged in water to 1 m (3ft) for up to 30 minutes without any leakage.

To ensure that each Kestrel meets this standard, they subject each one to a vacuum leak test after final assembly. One Kestrel product tester even sank it in a lake for a full day of fishing, then pulled it out and put it back to work - that's dedication! The appearance of Kestrel meters employed in underground coal mines is testimony to their dust-resistance.

Kestrel also drop-tests the Kestrel lineup to MIL-STD-810F (20 drops from 5' onto a hard surface.)