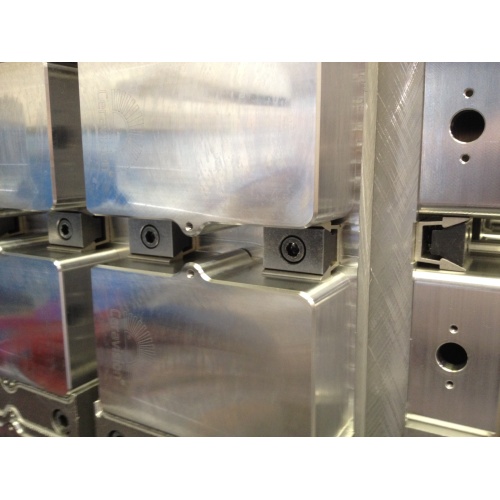

Mitee-Bite Uniforce Clamps: 60250 - 250

CAD88.72 EA

Specifications

Mitee-Bite Uniforce Clamps: 60375 - 375

CAD88.72 EA

Specifications

Mitee-Bite Uniforce Clamps: 60500 - 500

CAD88.72 EA

Specifications

Mitee-Bite Uniforce Clamps: 60750 - 750

CAD90.13 EA

Specifications

Mitee-Bite Uniforce Clamps: 61000 - 1000

CAD88.72 EA

Specifications

Mitee-Bite Uniforce Clamps: 61500 - 1500

CAD147.87 EA

Specifications

Mitee-Bite Uniforce Clamps: 62000 - 2000

CAD223.93 EA

Specifications

Mitee-Bite Uniforce Clamps: 80250 - 250

CAD88.72 EA

Specifications

Mitee-Bite Uniforce Clamps: 80375 - 375

CAD88.72 EA

Specifications

Mitee-Bite Uniforce Clamps: 80500 - 500

CAD88.72 EA

Specifications

Mitee-Bite Uniforce Clamps: 80750 - 750

CAD90.13 EA

Specifications

Mitee-Bite Uniforce Clamps: 81000 - 1000

CAD88.72 EA

Specifications

Mitee-Bite Uniforce Clamps: 81500 - 1500

CAD147.87 EA

Specifications

Mitee-Bite Uniforce Clamps: 82000 - 2000

CAD223.93 EA

Specifications

Recently Viewed

CAD281.68 EA

This all-purpose, non-conductive polymer flashlight is designed for the broadest range of lighting needs at the best value.

Multi-function On/Off push-button switch lets you choose three lighting m