STOP!!

YOU MUST ENSURE YOUR FIREARM IS FULLY UNLOADED AND PROVED SAFE BEFORE USING!!

PROVE

POINT THE FIREARM IN THE SAFEST AVAILABLE DIRECTION.

REMOVE ALL AMMUNITION.

OBSERVE THE CHAMBER.

VERIFY THE FEEDING PATH.

EXAMINE THE BORE.

ONCE SAFE, YOU MAY PROCEED TO THE NEXT STEP.

THIS GAS PORT ENLARGING IS ONLY REQUIRED ON SELECT 5.56 / 223 CALIBER BARRELS WITH RIFLE LENGTH GAS SYSTEMS

THIS IS NOT REQUIRED IF YOUR RAVEN IS CYCLING YOUR AMMUNITION OF CHOICE PERFECTLY.

TIME REQUIRED: THIS SHOULD TAKE NO MORE THAN 3-5 MINUTES

TOOLS REQUIRED:

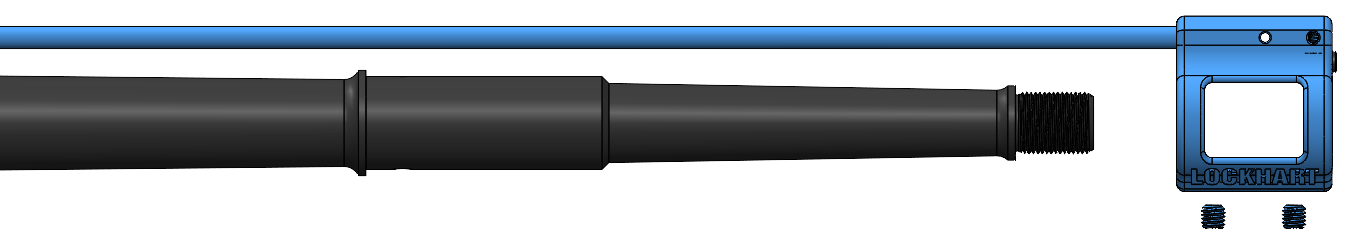

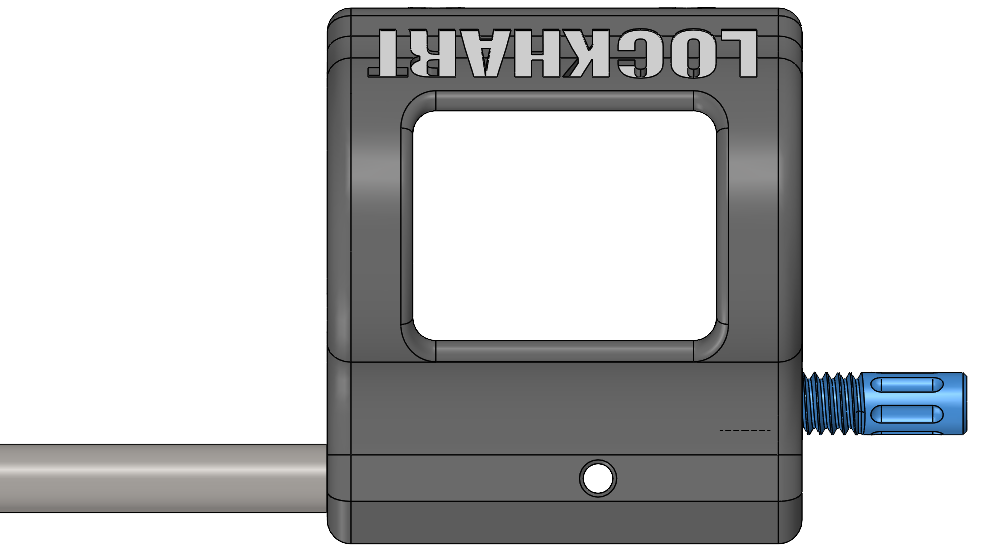

#4-40 SET SCREWS (SIDE AND TOP) 1/20 INCH HEX ALLEN KEY [0.050 INCH]

GAS BLOCK SCREW 5/64 INCH HEX ALLEN KEY [0.078 INCH]

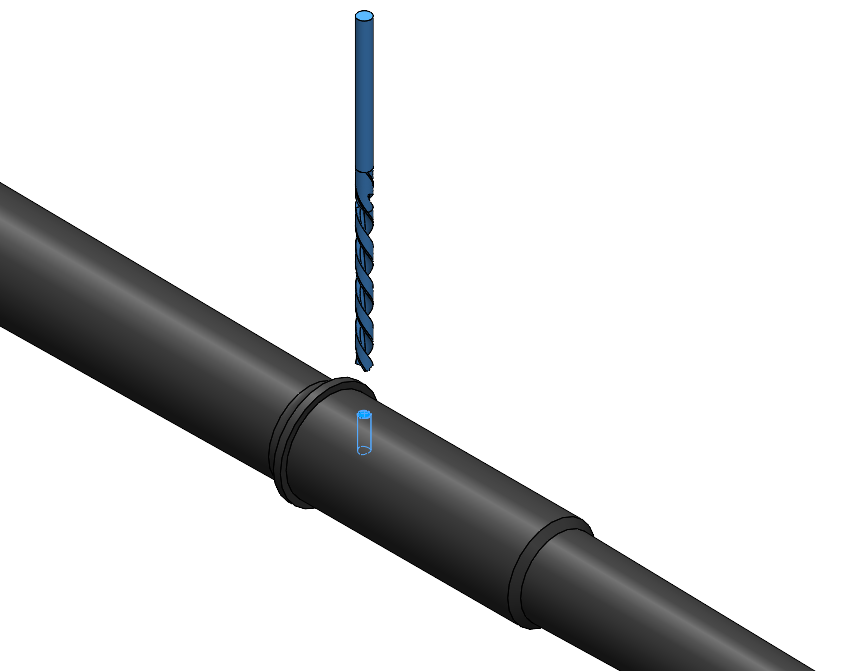

COBALT STEEL DRILL BIT 7/64 INCH [0.1094 INCH] AND POWER DRILL

WOODEN DOWEL ROD OR CLEANING ROD (RECOMMENDED)

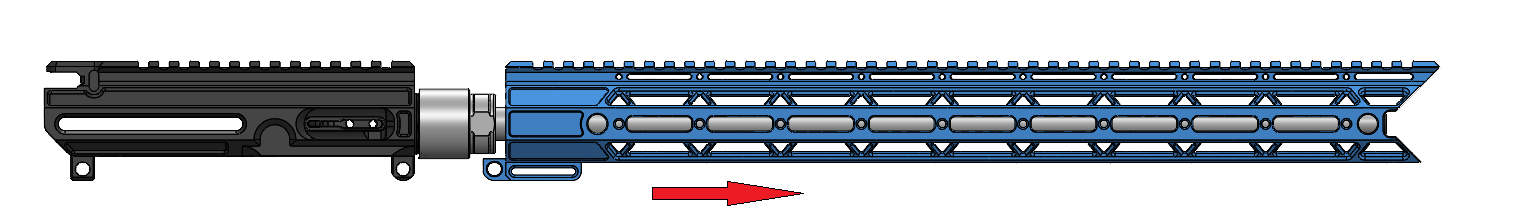

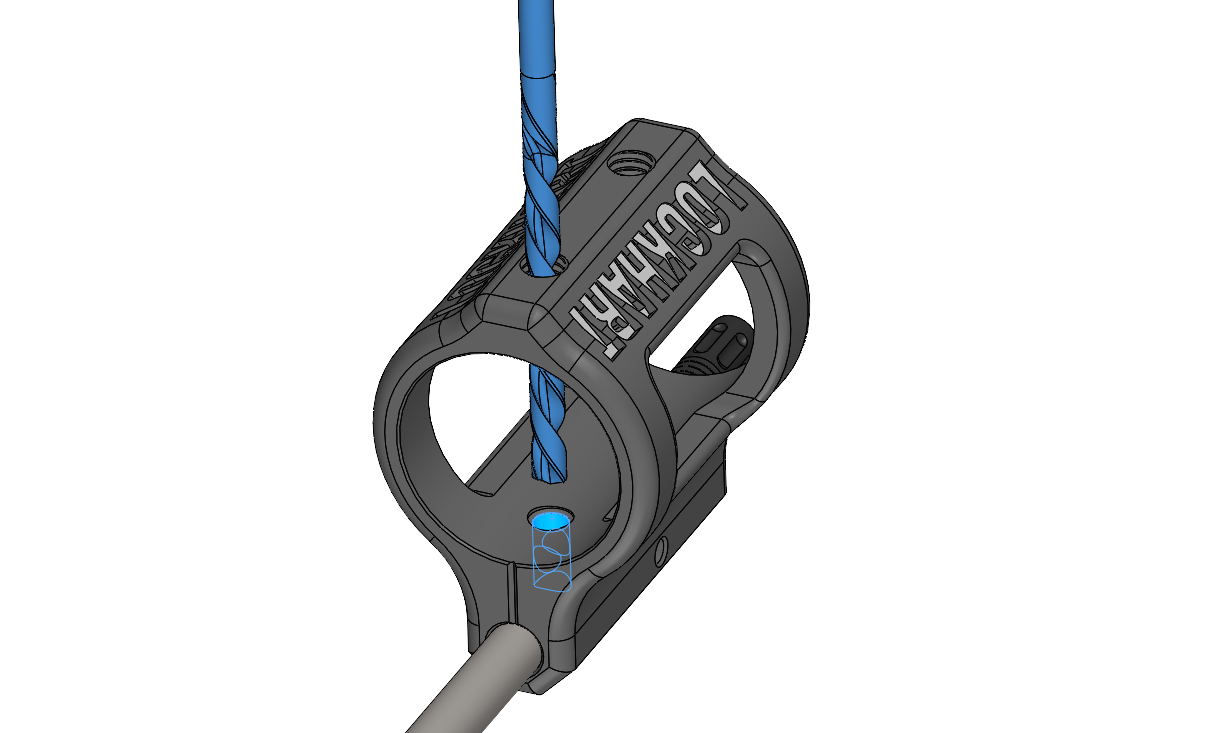

STEP 2: USING THE 5/64" ALLEN KEY, LOOSEN THE TWO (2) SET SCREWS ON THE BOTTOM SIDE OF THE ADJUSTABLE GAS BLOCK AND SLIDE IT OFF THE BARREL. LEAVE THE GAS TUBE ATTACHED TO THE GAS BLOCK. IT WILL SLIDE OUT AS ONE UNIT.

USING THE 7/64 DIAMETER DRILL BIT, CAREFULLY ENLARGE THE GAS PORT HOLE ON YOUR BARREL. DOING THIS WILL ALLOW MORE GAS TO TRAVEL THROUGH YOUR GAS TUBE TO CYCLE THE BOLT CARRIER. BLOW OUT ANY SMALL METAL SHAVINGS.

STEP 5: RETIGHTEN THE GAS ADJUSTMENT SCREW UNTI YOU FEEL AND HEAR (7) CLICKS.

LOOSEN THE SIDE LOCKING SETSCREW (COUNTER CLOCKWISE) THEN TIGHTEN THE TOP SETSCREW A LITTLE (CLOCKWISE). TEST AND REPEAT UNTIL AUDIBLE AND TACTCILE FEEL OCCURS WHEN ADJUSTING THE MAIN ADJUSTMENT SCREW. TIGHTEN SIDE LOCKING SET SCREW WHEN HAPPY.

STEP 7: GENTLY CYCLE BOLT CARRIER FIVE TIMES (5X) TO ENSURE CARRIER IS MATING WITH THE REINSTALLED GAS TUBE WITHOUT ISSUE.

YOUR INSTALLATION IS NOW COMPLETE AND READY FOR RANGE TESTING. MINOR ADJUSTMENT OF GAS BLOCK ADJUSTMENT SCREW MAY BE NEEDED TO ENSURE OPTIMAL CYCLING. FOLLOW PROCEDURE BELOW.

TEST IF FIREARM IS CYCLING PROPERLY

LOAD 1 MAGAZINE WITH (2) RDS. CHAMBER AND FIRE FIRST ROUND.

IF BOLT DOES NOT CYCLE REARWARD ENOUGH TO PICK UP AND LOAD THE SECOND ROUND IN THE CHAMBER, THEN GAS PRESSURE IS TOO LOW. ADJUST THE GAS BLOCK (2) CLICKS HIGHER. TURNING THE GAS ADJUSTMENT SCREW COUNTER CLOCKWISE ALLOWS MORE GAS TO FLOW TO THE BOLT CARRIER. TEST AND CONTINUE TO ADJUST IN SMALL INCREMENTS UNTIL THE RIFLE RELIABLY PICKS UP AND FIRES THE SECOND ROUND. BOLT CATCH SHOULD ENGAGE WHEN MAGAZINE IS EMPTY.

IF BOLT CATCH IS NOT ENGAGING AFTER MAGAZINE IS EMPTY

MOST COMMON ERROR IS BOLT IS CYCLING TOO FAST. DIAL GAS BLOCK DOWN SLIGHTLY TO DECREASE BOLT SPEED BY TURNING THE GAS ADJUSTMENT SCREW CLOCKWISE.