! NEVER DISASSEMBLE YOUR FIREARM BEYOND THE FIELD STRIPPING PROCEDURE OUTLINED IN THIS MANUAL.

IF YOU DO NOT UNDERSTAND THE INSTRUCTION IN THE MANUAL, STOP!

IMPROPER DISASSEMBLY OR REASSEMBLY OF YOUR FIREARM MAY BE DANGEROUS AND CAN LEAD TO SERIOUS INJURY OR DEATH.

CONTACT LOCKHART TACTICAL OR A QUALIFIED GUNSMITH FOR ADVICE BEFORE PROCEEDING WITH ANY ACTION.

‼ WARNING: BEFORE YOU BEGIN DISASSEMBLY OF YOUR RIFLE

YOU MUST FIRST INSPECT IT TO MAKE SURE THERE IS NOT A MAGAZINE IN THE MAGAZINE WELL, THE CHAMBER IS EMPTY, AND THE SAFETY SELECTOR IS ON SAFE.

! NEVER PERFORM OR ALLOW ANY ALTERATION OR REPLACEMENT OF PARTS IN YOUR FIREARM UNLESS PERFORMED BY A QUALIFIED GUNSMITH USING GENUINE LOCKHART TACTICAL PARTS.

IF YOU DO OTHERWISE, YOUR FIREARM MAY FUNCTION IMPROPERLY AND MAY CAUSE SERIOUS INJURY OR DEATH AND DAMAGE TO PROPERTY AS A RESULT.

! NEVER MANIPULATE, ADJUST OR CHANGE ANY OF THE INTERNAL COMPONENTS OF YOUR FIREARM UNLESS SPECIFICALLY INSTRUCTED TO DO SO IN THIS MANUAL. IMPROPER MANIPULATION OF ANY COMPONENTS OF THIS FIREARM BEYOND THE INSTRUCTIONS IN THIS MANUAL MAY AFFECT THE SAFETY AND RELIABILITY OF YOUR FIREARM AND MAY CAUSE SERIOUS INJURY OR DEATH.

! BE SURE ALL ACCESSORIES, GRIPS, SLINGS, SCOPES AND OTHER ACCESSORIES ARE COMPATIBLE WITH YOUR FIREARM AND THAT THE ACCESSORIES DO NOT INTERFERE WITH SAFE OPERATION. YOU MUST UNDERSTAND AND FOLLOW ALL OF THE INSTRUCTIONS IN THIS MANUAL, AS WELL AS THOSE THAT MAY BE SUPPLIED WITH YOUR AMMUNITION AND ANY ACCESSORY.

OPERATION: SEMIAUTOMATIC BLOWBACK ON PISTOL CALIBERS / DIRECT IMPINGEMENT ON RIFLE CALIBERS

RIFLE FINISH: ANODIZED OR CERAKOTE ON ALUMINUM SURFACES, DLC OR BLACK OXIDE / BLACK NITRIDE ON STEEL

CLEANING INSTRUCTIONS AND LUBRICATION

1. IS FIREARM UNLOADED AND SAFE BEFORE CLEANING?

2. CLEANING SHOULD BE DONE BY BRUSHING THE BARREL BORE AND CHAMBER WITH EITHER SLIP 2000 EWL OR A GOOD POWDER REMOVING SOLVENT AND BORE BRUSH.

3. AFTER USING A BORE BRUSH AND SOLVENT, SWAB OUT THE BORE AND CHAMBER WITH A PROPER BORE ROD AND PATCHES UNTIL THE PATCHES COME OUT CLEAN.

ENTIRE BARREL EXTERIOR SHOULD BE COATED WITH A VERY LIGHT COAT OF GUN OIL TO PREVENT ANY CHANCE OF SURFACE RUST.

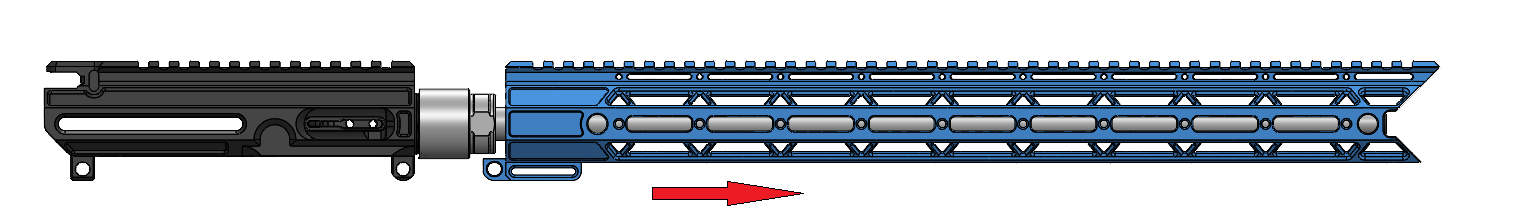

ALWAYS PUSH / PULL DIRT AND DEBRIS DOWN THE BORE TOWARDS THE MUZZLE. NEVER SCRAPE / PULL DIRT AND DEBRIS BACKWARDS AS THIS COULD LEAD TO DAMAGE OF YOUR RIFLE BARREL MUZZLE / CROWN.

AFTER CLEANING, PUSH A CLEAN PATCH SATURATED WITH EITHER SLIP 2000 EWL OR GUN OIL THROUGH THE BORE FOLLOWED BY A CLEAN DRY PATCH.

4. THE FIRING BOLT SHOULD BE DISASSEMBLED AND CLEANED IN A SIMILAR MANNER. LUBRICATE THE BOLT EXTERIOR WITH A LIGHT COAT OF SLIP 2000 AFTER REASSEMBLY.

DO NOT LUBRICATE THE FIRING PIN TIP AND FIRING BOLT FACE.

5. WIPE CLEAN AND LUBRICATE UPPER RECEIVER AND EJECTOR.

6. THE LOWER RECEIVER AND MAGWELL SHOULD BE WIPED CLEAN. APPLY A MINIMUM AMOUNT OF LUBRICANT ON THE TRIGGER GROUP SPRINGS.

SPRAY ON DRY LUBRICANT MAY BE USED SPARINGLY. DO NOT OIL. [NOTE: YOU MAY APPLY A VERY LIGHT COAT OF GUN OIL BETWEEN USES TO PROTECT AGAINST MOISTURE. IF YOU DO, YOU MUST BE SURE TO CLEAN AND REMOVE ANY EXCESS OIL FROM INSIDE THE ACTION OF YOUR RIFLE PRIOR TO SHOOTING.

FAILURE TO DO SO CAN RESULT IN EXCESS OIL AND UNBURNED GUNPOWDER BEING BLOWN OUT OF THE CHARGING HANDLE SLOT ON THE SIDE OF THE RECEIVER POTENTIALLY CAUSING SEVERE INJURY TO THE SHOOTER'S FACE AND EYES. ENSURE EYE PROTECTION IS ALWAYS WORN WHEN SHOOTING ANY FIREARM!

THE LOWER RECEIVER, MAGWELL, UPPER RECEIVER AND HANDGUARD ARE MADE FROM ALUMINUM. THEY DO NOT REQUIRE ANY OIL COATING!

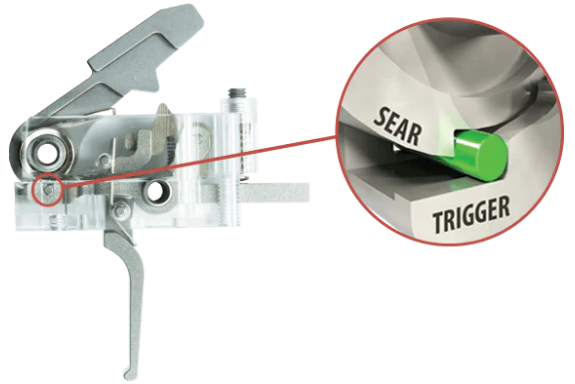

TRIGGERTECH TRIGGER CLEANING (IF APPLICABLE)

DUE TO THE PATENDED ROLLER SYSTEM TECHNOLOGY OF THE TRIGGERTECH TRIGGER PACK THEY TYPICALLY DO NOT NEED TO CLEANED AS OFTEN AS STANDARD TRIGGERS, HOWEVER MUCH LIKE ANY OTHER COMPONENT OF A FIREARM, IT IS STRONGLY SUGGESTED TO CLEAN THE TRIGGER PERIODICALLY.

WE SUGGEST USING A LIGHT SOLVENT, SUCH AS A LIGHTER FLUID, OR A BRAKE CLEANER MIXED WITH COMPRESSED AIR TO CLEAN OUT THE ENGAGEMENT SURFACES OF THE TRIGGER.

SEPERATE THE UPPER AND LOWER RECEIVERS AND UNDER CONTORL, RELEASE THE TRIGGER INTO THE FULLY FORWARD POSITION.

PAY SPECIAL ATTENTION TO CLEANING THE SEAR ENGAGEMENT SURFACE AS SHOWN IN THE IMAGE BELOW.

IF ANY CONTAMINANTS GET INTO THE ENGAGEMENT SURFACES, THE ROLLER WILL PUSH ANY DEBRIS OUT OF THE TRIGGER THROUGH THE CHANNELING IN THE HOUSING.

IN THE EVENT THAT THERE IS ALSO LUBE IN THE TRIGGER MIXED WITH THE CARBON, DIRT AND DUST, THEN USE A LIGHT SOLVENT ( LIKE LIGHTER FLUID IE. ZIPPO OR RONSOL ) AND COMPRESSED AIR, FOLLOWED BY 5-10 DRY FIRES OF THE TRIGGER.

NOTE: DO NOT ALLOW THE TRIGGER TO SLAM INTO THE LOWER RECEIVER AS OVER TIME THIS CAN CAUSE DAMAGE!

BEFORE FIRING CHECK LIST:

1) IS FIREARM UNLOADED AND SAFE BEFORE INSPECTING?

2) DO I HAVE ALL MY SAFETY EQUIPMENT?

3) IS ALL AMMUNITION VERIFIED TO BE CORRECT FOR MY FIREARM?

4) ARE ALL VISIBILE HEX HEAD SCREWS SNUG?

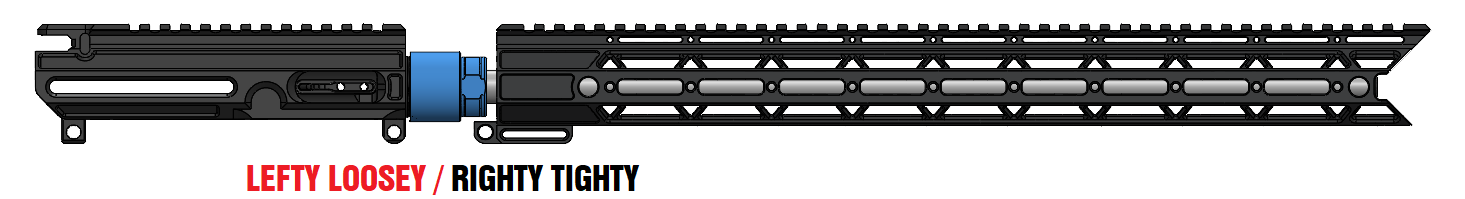

5) IS BARREL NUT UNDER HANDGUARD TIGHT?

6) IS FIREARM CLEANED, OILED AND BARREL FREE OF OBSTRUCTIONS?

NOTE: A LOOSE BARREL CAN CAUSE ISSUES AS DESCRIBED IN DETAIL HERE: STOPPAGES