FIREARMS LIKE ANY MECHANICAL TOOL ARE CAPABLE OF MALFUNCTIONING. OFTEN REFERRED TO AS STOPPAGES, THESE SAME STOPPAGES CAN TYPICALLY HAPPEN ON ANY TYPE OF FIREARM.

THERE ARE A FEW COMMON REASONS FOR STOPPAGES.

USER ERROR, MAGAZINE MALFUNCTION, FIREARM MALFUNCTION OR AMMUNITION MALFUNCTION.

STOPPAGE: HANGFIRE (DELAYED FIRING)

A LIVE ROUND IS IN THE CHAMBER, YOU AIM AT THE TARGET AND PULL THE TRIGGER. ALL YOU HEAR IS THE HAMMER STRIKE THE FIRING PIN BUT NOTHING HAPPENS YET. THIS IS CAUSED BY A FAULTY AMMUNITION PRIMER OR FAULTY GUN POWDER IN THE CASING. AFTER A SHORT PERIOD OF TIME, THE ROUND FIRES.

THE FIX: ENSURE YOU CONTINUE POINTING AT YOUR TARGET UNTIL THE ROUND FIRES. IT SHOULD BE WELL UNDER (60 SECONDS). UNLOAD THE FIREARM AND RELOAD WITH NEW AMMUNITION.

STOPPAGE: MISFIRE (ROUND DOES NOT FIRE)

A LIVE ROUND IS IN THE CHAMBER, YOU AIM AT THE TARGET AND PULL THE TRIGGER. ALL YOU HEAR IS THE HAMMER STRIKE THE FIRING PIN BUT NOTHING HAPPENS. YOU COUNT TO (60 SECONDS) AND STILL NOTHING HAPPENS. THIS IS A FAULTY PRIMER.

THE FIX: ENSURE AS SOON AS THIS STOPPAGE OCCURS, ENSURE YOU COUNT TO (60) SECONDS, AS THIS MAY BE A HANGFIRE! ONLY AFTER (60) SECONDS DOES THIS BECOME A MISFIRE. ONCE THE WAITING PERIOD IS OVER, UNLOAD THE FIREARM AND RELOAD WITH NEW AMMUNITION.

STOPPAGE: "THE CLICK"

A LIVE ROUND IS IN THE CHAMBER, YOU AIM AT THE TARGET AND PULL THE TRIGGER. ALL YOU HEAR IS THE HAMMER STRIKE THE FIRING PIN BUT NOTHING HAPPENS. THIS COULD POTENTIALLY BE A HANGFIRE OR MISFIRE. YOU WON'T KNOW UNTIL AFTER (60) SECONDS. IF YOU RELOAD FRESH AMMUNITION AND IT HAPPENS AGAIN, IT MOST LIKELY IS A DAMAGED OR WORN OUT FIRING PIN.

THE FIX: REPLACE THE FIRING PIN

STOPPAGE: BOLT NOT FULLY IN BATTERY

A COMMON USER ERROR WOULD BE WHILE LOADING A FIREARM, THE USER PULLS THE CHARGING HANDLE REARWARD AND INSTEAD OF FULLY RELEASING THE FIRING BOLT, THEY KEEP THEIR HAND ON THE CHARGING HANDLE AND "RIDE THE HANDLE FORWARD" THIS CAN CAUSE A FAILURE TO FEED. MEANING THE ROUND DID NOT FEED PROPERLY INTO THE CHAMBER.

THIS HAPPENS TYPICALLY BECAUSE WHILE THE USER IS "RIDING THE HANDLE FORWARD" THEY ARE SLOWING DOWN THE FORWARD MOVEMENT OF THE FIRING BOLT, THUS DECREASING THE AMOUNT OF SPRING FORCE THE BUFFER SPRING HAS TO ENSURE THE BOLT IS IN BATTERY AND READY TO FIRE.

THE FIX: STOP RIDING THE CHARGING HANDLE AND INSTEAD SIMPLY PULL THE CHARGING HANDLE FULLY REARWARDS AND RELEASE IT!

STOPPAGE: DOUBLE FEED

TWO THINGS CAN’T OCCUPY THE EXACT SAME SPACE AT THE SAME TIME, BUT OCCASIONALLY CARTRIDGES TRY TO IN THE CHAMBER, RESULTING IN A DOUBLE- FEED STOPPAGE THIS MALFUNCTION OCCURS WHEN ONE ROUND FROM THE MAGAZINE IS PROPERLY FED INTO THE CHAMBER, BUT THE FOLLOWING ROUND IN THE MAGAZINE JUMPS OUT FROM BEHIND AND TRIES TO JOIN IT. THE RESULT IS A CHAMBERED ROUND WITH A SECOND ROUND JAMMED UP AGAINST ITS BASE, STOPPING THE SLIDE FROM GOING INTO BATTERY.

THIS MALFUNCTION OCCURS WHEN ONE ROUND FROM THE MAGAZINE IS PROPERLY FED INTO THE CHAMBER, BUT THE FOLLOWING ROUND IN THE MAGAZINE JUMPS OUT FROM BEHIND AND TRIES TO JOIN IT. THE RESULT IS A CHAMBERED ROUND WITH A SECOND ROUND JAMMED UP AGAINST ITS BASE, STOPPING THE SLIDE FROM GOING INTO BATTERY.

THIS CAN ALSO BE CAUSED BY USER ERROR IF THE CHAMBER IS ALREADY LOADED AND THE USER TRIES TO LOAD ANOTHER ROUND.

IT COULD ALSO BE CAUSED IF A ROUND IS LOADED IN THE CHAMBER AND THE EXTRACTOR CLAW ON THE BOLT FAILS. IF THE EXTRACTOR FAILS, THEN EACH TIME THE FIRING BOLT IS CYCLED REARWARD THE CARTRIDGE IN THE CHAMBER WILL REMAIN IN PLACE WITHOUT BEING EXTRACTED AND EJECTED OUT OF THE FIREARM.

THE FIX: REMOVE THE MAGAZINE, PULL THE CHARGING HANDLE REARWARD AND THE STUCK CARTRIDGE SHOULD FALL FREE. RELEASE THE CHARGING HANDLE AND THE BOLT SHOULD CLOSE PROPERLY INTO BATTERY. REINSERT THE MAGAZINE AND THE FIREARM IS NOW READY TO USE AGAIN.

STOPPAGE: FAILURE TO FEED

THIS CAN COMMONLY OCCUR WITH HOLLOW POINT (HP) AND TRUNCATED CONE (TC) SHAPED PROJECTILES DUE TO THEIR DIFFERENT GEOMETRY WHICH MAKES IT HARDER TO FEED INTO THE CHAMBER.

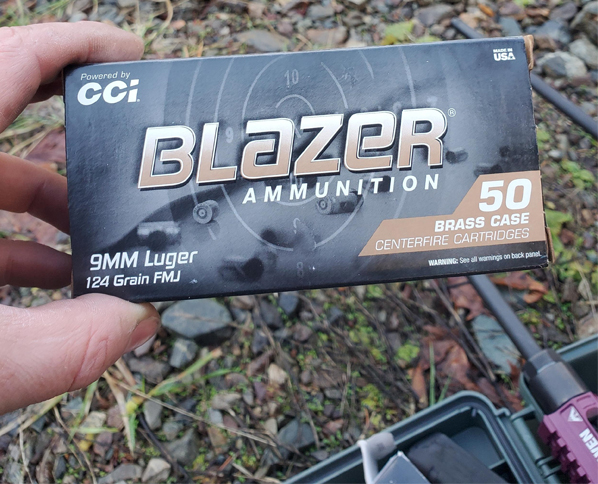

CERTAIN BRANDS OF AMMUNITION ALSO FEED BETTER THAN OTHERS IN SOME CASES. WE RECOMMEND USING BLAZER 115 GR OR 124GR BRASS CASED AMMUNITION IT CAN ALSO BE CAUSED BY DAMAGED MAGAZINE FEED LIPS, FAULTY MAGAZINE SPRINGS OR FAULTY MAGAZINE FOLLOWERS.

IT CAN ALSO BE CAUSED BY DAMAGED MAGAZINE FEED LIPS, FAULTY MAGAZINE SPRINGS OR FAULTY MAGAZINE FOLLOWERS.

THE FIX: USE FULL METAL JACKET ROUND NOSE PROJECTILES. IF THE PROBLEM IS NOW GONE, IT IS CONFIRMED TO BE NON-SUITABLE AMMUNITION. IF THE PROBLEM PERSISTS, ENSURE YOU ARE USING THE MAGAZINES SUPPLIED BY LOCKHART TACTICAL.

STOPPAGE: FAILURE TO EXTRACT

THE CATRIDGE WON'T EXTRACT FROM THE CHAMBER EVEN AFTER YOU CYCLE THE FIRING BOLT NUMEROUS TIMES. THE EXTRACTOR CLAW IS MOST LIKELY BROKEN. THIS IS A WEAR PART THAT WILL EVENTUALLY FAIL AND WILL NEED REPLACING.

THE FIX: SIMPLY REPLACE THE EXTRACTOR CLAW.

STOPPAGE: FAILURE TO EJECT

THE CARTRIDGE WON'T EJECT FROM THE FIREARM AFTER BEING EXTRACTED FROM THE CHAMBER. OVER TIME THE EJECTOR COULD BECOME DAMAGED.  THE FIX: SIMPLY REPLACE THE EJECTOR.

THE FIX: SIMPLY REPLACE THE EJECTOR.

STOPPAGE: UNSUPPORTED AMMUNITION DURING FIRING

IN ALL FIREARMS, THE AMMUNITION MUST BE FULLY SUPPORTED IN THE CHAMBER BEFORE FIRING.

IF THE AMMUNITION IS FIRED WHILE SLIGHTLY OUT OF BATTERY, THE CASING WILL NOT BE FULLY SUPPORTED BY THE BOLT FACE AND THE CHAMBER. THIS CAN CAUSE THE CASING TO RUPTURE AND TEAR.

NOTE! IF THIS OCCURS, STOP FIRING IMMEDIATELY TO DIAGNOSE THE ISSUE!

THIS CAN SEND SHRAPNEL FLYING OUT OF THE EJECTION PORT!

ON FIREARMS, THE MOST COMMON CAUSES ARE

1) IMPROPER MATING BETWEEN THE CHAMBER AND BOLT

2) BARREL / BARREL NUT NOT FULLY SEATED

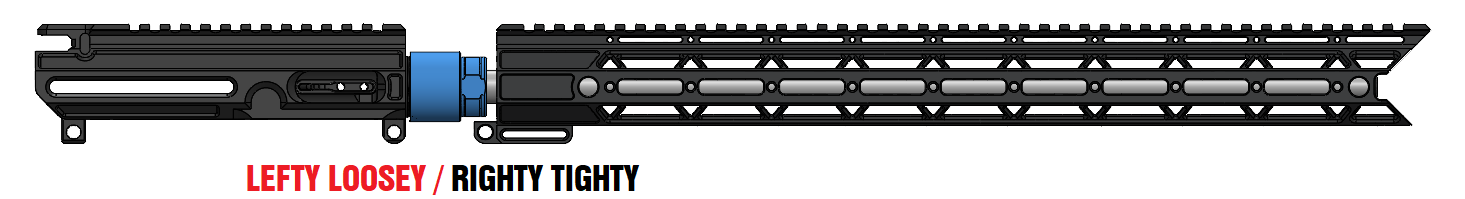

IF THE BARREL NUT HAS SLIGHTLY LOOSENED / BACKED OFF IT CAN ALLOW THE BARREL TO MOVE FORWARD A SMALL AMOUNT. THIS SMALL AMOUNT IS ENOUGH THAT THE CASING CAN BE UNSUPPORTED.

3) CLIENT USES GRINDER OR DREMEL TOOL TO MODIFY CHAMBER

DO NOT ALTER OR MODIFY YOUR BOLT OR CHAMBER! THIS CAN CAUSE IRREPARABLE DAMAGE / DESTROY YOUR PARTS WHILE CAUSING SAFETY ISSUES!

THE FIX: BECAUSE THE RAVEN IS A MULTI-CALIBER CAPABLE FIREARM WITH TOOL-LESS TAKE DOWN FEATURES YOU MUST ENSURE THAT BEFORE USING THE RIFLE THAT ALL PREVENTATIVE MAINTENANCE (LINK) STEPS ARE ALWAYS FOLLOWED.

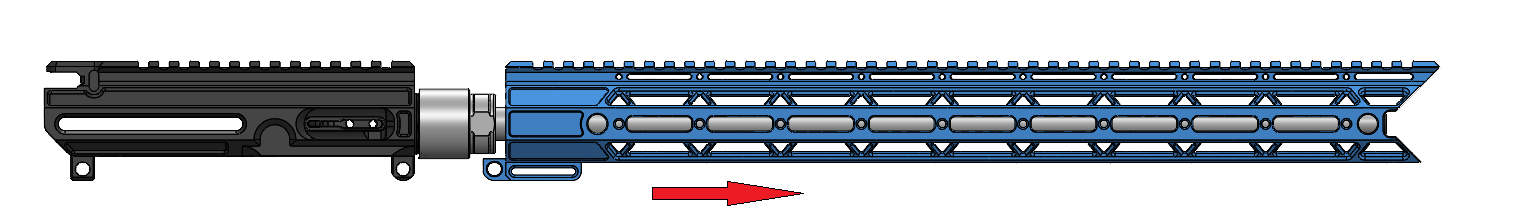

ENSURE YOUR BARREL NUT IS FULLY TIGHTENED. SIMPLY REMOVE YOUR UPPER RECEIVER FROM THE LOWER THEN SLIDE THE HANDGUARD FORWARD ABOUT (4) INCHES TOWARDS THE BARREL MUZZLE. THIS WILL ALLOW YOU TO SEE AND INSPECT THE BARREL NUT.

IF YOU DO NOT PLAN ON UTILIZING YOUR RAVEN'S TOOL LESS BARREL REMOVAL FEATURE AND INSTEAD PLAN ON KEEPING IT AS A DEDICATED CALIBER, YOU MAY CHOOSE TO INSTALL BLUE LOCTITE ON THE BARREL THREADS THEN TORQUE DOWN THE BARREL NUT.

WARNING: RED LOCTITE IS EXTREMELY DIFFICULT TO REMOVE IN THE FUTURE. WE DO NOT RECOMMEND IT!

TORQUE SPEC MUST BE BETWEEN 30 AND 80 FOOT POUNDS!