NOW THAT YOU'VE BECOME FAMILIARIED WITH YOUR NEW RAVEN IT'S TIME TO TAKE IT TO THE RANGE!

YOUR RIFLE CAME WITH A 416R STAINLESS STEEL BARREL WITH 5R BUTTON RIFLING (UNLESS STATED OTHERWISE DURING YOUR PURCHASE).

5R BUTTON RIFLING HAS BEEN PRAISED SINCE ITS INVENTION FOR THE INCREDIBLE ACCURACY AND PROJECTILE STABILITY IT ADDS.

BEFORE DIVING INTO THE SPECIFICS OF WHAT 5R IS, LETS COVER THE BASICS OF RIFLING. RIFLING CONSISTS OF LANDS (THE PLATEAUS THAT INTERFACE WITH BULLETS) AND GROOVES (THE CUTS INTO A BORE) WHICH ARE MANUFACTURED TO HELP STABILIZE A BULLET BY IMPARTING GYROSCOPIC TWIST ONTO IT IN THE BARREL OF A FIREARM.

AS A BULLET PASSES THROUGH A BARREL THE LANDS OF A BARREL DIRECTLY CUT/SQUEEZE INTO THE PROJECTIVE FORCING IT TO FOLLOW THE PATH OF THE RIFLING. THIS IS WHY BULLETS HAVE UNIQUE GROOVING ON THEM IF THEY ARE RECOVERED INTACT.

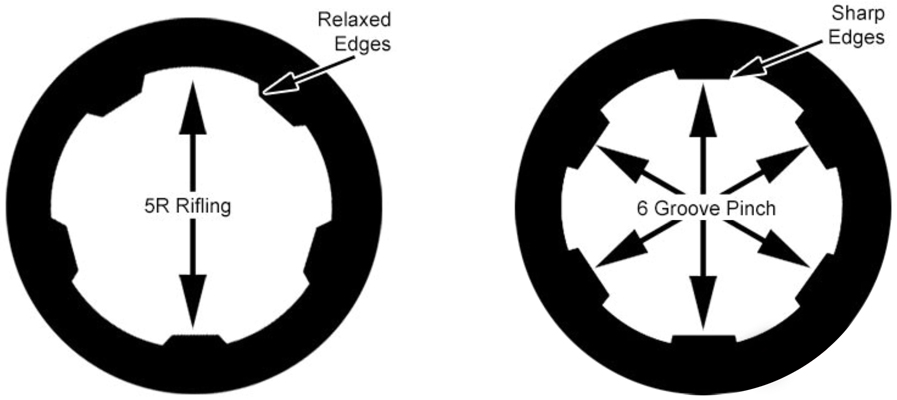

“CONVENTIONAL” RIFLING USES EITHER 6 OR 4 SYMMETRICAL LANDS AND GROOVES ON THE BULLET. EACH OF THE LANDS (THE RAISED PORTION OF THE RIFLING) ARE DIRECTLY OPPOSITE ONE ANOTHER. LIKEWISE THE GROOVES ARE OPPOSITE OF ONE ANOTHER. THE VAST MAJORITY OF BARRELS OTHER COMPANIES USE IS CONVENTIONALLY RIFLED.

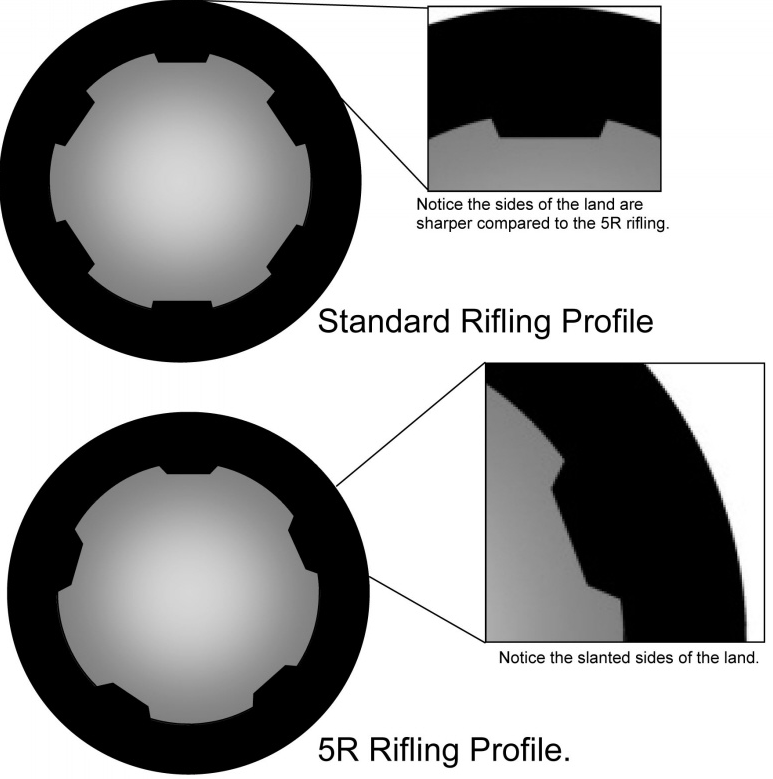

5R IS AN IMPROVEMENT OVER CONVENTIONAL RIFLING BY CHANGING THE SHAPE AND CONFIGURATION OF THE LANDS AND GROOVES. CONVENTIONAL RIFLING, WHILE EFFECTIVE, CAN BE IMPROVED UPON IN TWO WAYS.

- 1. CONVENTIONAL RIFLING HAS SHARP 90-DEGREE CORNERS FROM THE TOP OF THE LAND TO THE BOTTOM OF THE GROOVE.

- 2.CONVENTIONAL RIFLING HAS LANDS AND GROOVES OPPOSING ONE ANOTHER.

5R RIFLING IMPROVES UPON THIS BY USING 5 LANDS AND GROOVES OVER THE EVEN NUMBERS WHICH PUTS LANDS OPPOSITE OF GROOVES. FURTHER, THE TRANSITION FROM THE TOP OF THE LAND TO THE GROOVE IS SLOPED.

SECONDLY, BY SLOPING THE TRANSITION TO THE GROOVE, THE BARRELS BECOME MUCH EASIER TO CLEAN. IN A CONVENTIONALLY RIFLED PLATFORM, THESE CORNERS BECOME DEPOSITORIES FOR LEAD AND SUPERHEATED MATERIALS LEFT AFTER SHOOTING. CLEANING SUPPLIES HAVE A HARD TIME REACHING THESE CORNERS AS THEY ARE INCREDIBLY SMALL. BY SLOPING IT, CLEANING SUPPLIES ARE EASILY ABLE TO GET TO THE DEPOSITS.

AMMUNITION SELECTION

ALTHOUGH EACH RAVEN RIFLES IS MANUFACTURED TO THE SAME TOLERANCES, REMEMBER THAT NOT ALL AMMUNITION IS CREATED EQUAL.

VARIATIONS BETWEEN DIFFERENT AMMUNITION MANUFACTURERS IN BULLET PROFILE, CASE DIAMETER, AND BULLET COMPOSITION CAN SIGNIFICANTLY IMPACT AMMUNITION FEEDING. IT'S POSSIBLE THAT EVEN DIFFERENT LOTS OF AMMUNITION FROM THE SAME MANUFACTURER COULD DIFFER.

IF YOU ARE EXPERIENCING FEEDING DIFFICULTIES UNRELATED TO THE MAGAZINE, CONSIDER TRYING DIFFERENT TYPES AND BRANDS OF AMMUNITION TO DETERMINE WHICH PERFORMS BEST IN YOUR RAVEN.

NOTE: CAST LEAD BULLETS ARE NOT RECOMMENDED!

BARREL NITRIDE COATING

YOUR BARREL HAS BEEN NITRIDE COATED TO MINIMIZE REFLECTIONS, INCREASE SURFACE HARDNESS AND ADDED CORROSION RESISTANCE.

DURING THE PROCESS OF ADDING THE BLACK NITRIDE, A TWO-PART SURFACE LAYER IS FORMED. AN OUTER IRON NITRIDE LAYER WITH A NITROGEN DIFFUSION LAYER BELOW IT.

DUE TO THESE NITRIDE LAYERS IN THE CHAMBER, ON SOME BARRELS IT CAN BE EXTRA TIGHT CAUSING POTENTIAL TEMPORARY FEED ISSUES WHILE THE BARREL IS STILL BRAND NEW. TYPICALLY AFTER AROUND 75-100 ROUNDS, THE CHAMBER BREAK IN WILL BE COMPLETE AND FEELING PERFECTLY.

ONCE AGAIN! IF YOU BARREL IS HAVING SOME FEEDING ISSUES WHILE IT'S NEW OUT OF THE BOX! DO NOT WORRY. THIS IS VERY TEMPORARY WHILE YOU BREAK THE CHAMBER IN.

BREAK IN PROCEDURE

STEP 1: CLEAN THE ENTIRE FIREARM INCLUDING THE BORE AND CHAMBER.

RUN A SOLVENT-SOAKED PATCH THROUGH THE BARREL, STARTING AT THE CHAMBER SIDE AND PULLING TOWARDS THE MUZZLE. REPEAT THIS WITH A NEW SOAKED PATCH 3 TIMES OR UNTIL NO BLACK IS SHOWING ON THE PATCH. A BORE SNAKE WOULD ALSO WORK GREAT!

PARTICULARLY SCRUB THE CHAMBER WITH A NYLON OR BRASS BRUSH SOAKED WITH SOLVENT.

ONCE THE CHAMBER IS FULLY CLEANED, PULL DRY CLEANING PATCHES (WITHOUT SOLVENT) THROUGH THE CHAMBER AND BORE UNTIL THEY COME OUT CLEAN AND DRY. ONCE AGAIN A BORE SNAKE IS EXCELLENT TO USE! LUBRICATE THE BOLT AND BOLT CARRIER WITH A LIGHT COAT OF FIREARM OIL.

STEP 2: ADJUST GAS BLOCK TO STARTING POSITION

TURN THE GAS BLOCK ADJUSTMENT SCREW CLOCKWISE UNTIL IT IS SNUG. THEN CAREFULLY TURN THE ADJUSTMENT SCREW 15 CLICKS COUNTER CLOCKWISE.

STEP 3: FIRE 75-100 ROUNDS THROUGH THE RIFLE. FINE TUNE THE ADJUSTABLE GAS BLOCK AFTER 40 ROUNDS HAVE BEEN FIRED.

IF ANY FAILURE TO FEED OR OTHER STOPPAGE OCCURS, SIMPLY CORRECT THE STOPPAGE AND CONTINUE FIRING.

CLEARING STOPPAGES GUIDE

NOTE: ENSURE TO CAREFULLY INSPECT THAT THE BOLT IS FULLY FORWARD BEFORE EACH SHOT. DO NOT RAPID FIRE.

WHILE THE CHAMBER IS BREAKING IN, ITS POSSIBLE THAT THE BOLT MAY NOT BE FULLY FOWARD DUE TO A STOPPAGE. DO NOT FIRE YOUR RIFLE UNLESS THE BOLT IS FULLY FORWARD!

A SIMPLE WAY TO TEST IF THE FIREARM IS CYCLING PROPERLY, IS TO LOAD MULTIPLE MAGAZINES WITH 2 ROUNDS EACH. CHAMBER AND FIRE THE FIRST ROUND.

IF THE BOLT DOES NOT CYCLE REARWARD ENOUGH TO PICK UP AND LOAD THE SECOND ROUND IN THE CHAMBER, THEN THE GAS PRESSURE IS TOO LOW. SIMPLY ADJUST THE PRESSURE TO BE SLIGHTLY HIGHER. CONTINUE TO ADJUST IN SMALL INCREMENTS UNTIL THE RIFLE RELIABLY PICKS UP THE SECOND ROUND.

AFTER THE SECOND ROUND IS FIRED, THE BOLT CATCH SHOULD AUTOMATIALLY ENGAGE. IF THE BOLT CATCH IS NOT ENGAGING, EITHER THE BOLT IS STILL NOT CYCLING REARWARD ENOUGH (IN WHICH CASE, MORE GAS PRESSURE IS NEEDED), OR YOU ALLOWED TOO MUCH GAS PRESSURE TO PUSH ON THE BOLT WHICH IS CAUSING IT TO CYCLE TOO QUICKLY FOR THE BOLT CATCH TO ENGAGE. IF THAT IS THE CASE, ADJUST THE GAS PRESSURE TO BE LOWER UNTIL THE BOLT CATCH WORKS.

NOTE: FINE TUNE THE ADJUSTABLE GAS BLOCK AFTER AT LEAST (40) ROUNDS HAVE BEEN FIRED.

STEP 4: CLEAN THE FIREARM AGAIN AND INSPECT THAT THE BARREL NUT AND ALL OTHER SCREWS / NUTS ARE STILL TIGHT AS PER CLEARING STOPPAGES GUIDE

STEP 5: CONTINUE SAFELY USING YOUR RIFLE AND ENJOY!

YOUR RIFLE SHOULD BE FEEDING PERFECTLY NOW. IF YOU ARE EXPERIENCING FEEDING PROBLEMS, PLEAE SEE OUR AMMUNITION GUIDE