STOP!!

YOU MUST ENSURE YOUR FIREARM IS FULLY UNLOADED AND PROVED SAFE BEFORE USING!!

PROVE

POINT THE FIREARM IN THE SAFEST AVAILABLE DIRECTION.

REMOVE ALL AMMUNITION.

OBSERVE THE CHAMBER.

VERIFY THE FEEDING PATH.

EXAMINE THE BORE.

ONCE SAFE, YOU MAY PROCEED TO THE NEXT STEP.

STEP 1:

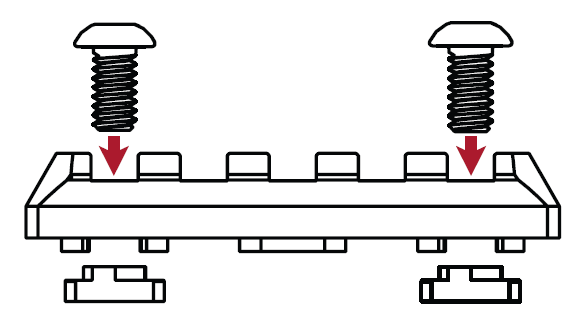

INSTALL T-NUTS AND SCREWS TO THE RAIL SEGMENT OR ACCESSORY. INSERT THE

SCREWS THROUGH THE TOP OF THE ACCESSORY AND THREAD ON THE T-NUTS WITH

THE “STEM” OF THE NUT FACING UP.

STEP 2:

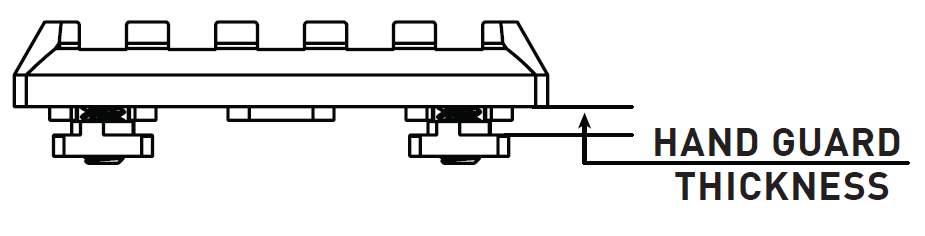

ADJUST THE T-NUTS FOR MOUNTING SURFACE THICKNESS. THE DISTANCE

BETWEEN THE BOTTOM OF THE ACCESSORY (NOT THE LUG) AND THE TOP “FLAT” OF

THE T-NUT SHOULD BE JUST WIDER THAN MOUNTING SURFACE THICKNESS.

STEP 3:

STEP 3:

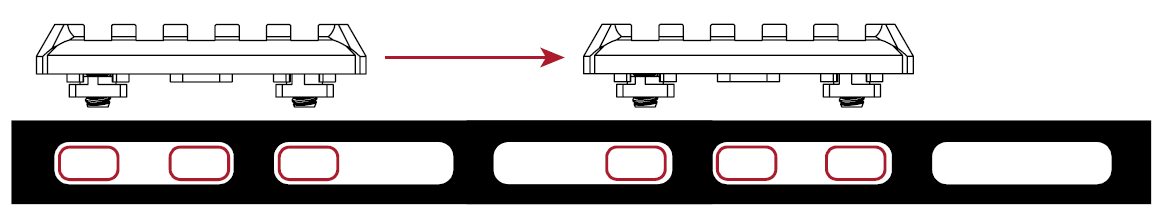

CHOOSE A MOUNTING LOCATION. YOUR M-LOK ACCESSORY CAN BE ADJUSTED IN 20MM INCREMENTS (1/2 SLOT LENGTH)

STEP 4:

STEP 4:

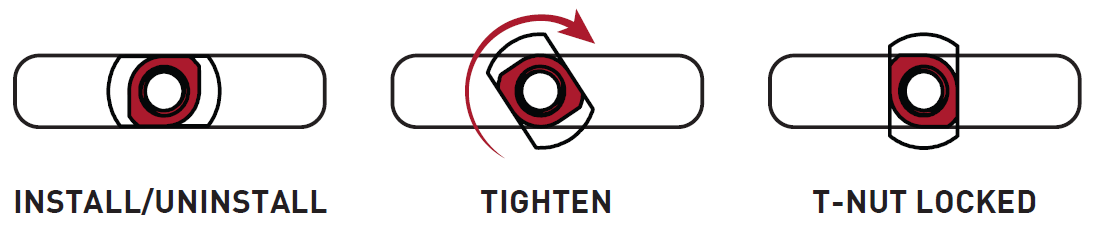

ALIGN THE T-NUTS AND INSERT THE ACCESSORY. ROTATE T-NUTS INLINE WITH THE SLOT AND INSERT THE LUGS/T-NUTS INTO THE SLOT IN THE DESIRED LOCATION.

STEP 5:

TIGHTEN SCREWS. USING A HEX WRENCH IN THE SCREW HEAD, PUSH DOWN

TO FULLY SEAT THE SCREW IN THE ACCESSORY, THEN TURN CLOCKWISE TO TIGHTEN.

THE T-NUT SHOULD ROTATE 90 DEGREES ACROSS THE SLOT AND STOP ROTATING,

TIGHTENING DOWN AS YOU CONTINUE TO TURN. VISUALLY CONFIRM THAT THE NUTS

ARE ROTATED, IF POSSIBLE.

CONTINUE TIGHTENING UNTIL ACCESSORY IS SECURE,

BUT DO NOT EXCEED MAXIMUM TORQUE VALUES. EXCEEDING TORQUE VALUES

MAY DAMAGE MOUNTING SURFACE.

MAXIMUM INSTALLATION TORQUE:

METAL ACCESSORIES TO METAL HAND GUARDS: 35 IN/LBS

POLYMER OR METAL ACCESSORIES TO POLYMER HAND GUARDS: 15 IN/LBS

POLYMER ACCESSORIES TO METAL HAND GUARDS: 15 IN/LBS